Quanhua Mining Machinery

QUANHUA MINING MACHINERY

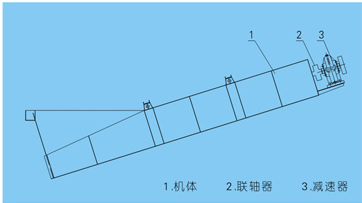

LS type sand washing machine

When the spiral sand washing machine is working, the motor drives the impeller to slowly rotate through a triangular belt, reducer, and gear, and the sand and gravel enter the washing tank from the feeding groove. Driven by the impeller, they roll and grind each other to remove impurities that cover the surface of the sand and gravel, while also damaging the water vapor layer that covers the sand particles, in order to facilitate dehydration; At the same time, add water to form a strong water flow, timely remove impurities and small specific gravity foreign objects, and discharge them from the overflow outlet washing tank to complete the cleaning function. The clean sand and gravel are taken away by the blades, and finally the sand and gravel are poured into the discharge groove from the rotating impeller to complete the cleaning effect of the sand and gravel.

Performance characteristics of sand washing machine:

1. The sand washing machine has a simple structure and stable performance. The impeller drive bearing device is isolated from water and water receiving materials, greatly avoiding the occurrence of bearing damage caused by immersion, sand, and pollutants.

2. This type of sand washing machine has obvious advantages compared to traditional spiral sand washing machines when used for sand washing in sand and gravel fields, as follows:

<1> The loss of medium and fine sand and stone powder is minimal, and the fineness modulus of the washed construction sand grade meets the national standards of "Construction Sand" and "Construction Pebble and Crushed Stone".

<2> This machine has almost no vulnerable parts except for the screen.

<3> Long service life, no need for maintenance for a long time. The sand washing machine has high cleanliness, reasonable structure, large processing capacity, low power consumption, and less sand loss during the sand washing process. Especially, the transmission part of the sand washing machine is isolated from water and sand, so its failure rate is much lower than the commonly used sand washing machines. It is a suitable choice for upgrading and upgrading the domestic sand washing industry.

Technical parameters:model Number of spirals Spiral diameter(mm) Tank length(mm) Feed particle-size(mm) Processing capacity(m/h) Speed(r/min) power(kw) water consumption(t/h) weight(t) LS800 1 800 7500 <=10 30-50 16 7.5 10-80 6.2 LS1000 1 1000 7500 <=10 50-70 15 11 20-100 7.56 LS1300 1 1200 7500 <=10 60-100 12 11 20-150 9.43 LS1500 1 1400 9000 <=10 80-130 10 15 40-300 11.46 2LS1000 2 1000 9000 <=10 100-160 15 11×2 30-200 14.2 2LS1500 2 1400 9000 <=10 120-200 10 15×2 60-300 13.6

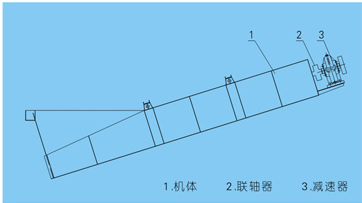

LS type sand washing machine

When the spiral sand washing machine is working, the motor drives the impeller to slowly rotate through a triangular belt, reducer, and gear, and the sand and gravel enter the washing tank from the feeding groove. Driven by the impeller, they roll and grind each other to remove impurities that cover the surface of the sand and gravel, while also damaging the water vapor layer that covers the sand particles, in order to facilitate dehydration; At the same time, add water to form a strong water flow, timely remove impurities and small specific gravity foreign objects, and discharge them from the overflow outlet washing tank to complete the cleaning function. The clean sand and gravel are taken away by the blades, and finally the sand and gravel are poured into the discharge groove from the rotating impeller to complete the cleaning effect of the sand and gravel.

Performance characteristics of sand washing machine:

1. The sand washing machine has a simple structure and stable performance. The impeller drive bearing device is isolated from water and water receiving materials, greatly avoiding the occurrence of bearing damage caused by immersion, sand, and pollutants.

2. This type of sand washing machine has obvious advantages compared to traditional spiral sand washing machines when used for sand washing in sand and gravel fields, as follows:

<1> The loss of medium and fine sand and stone powder is minimal, and the fineness modulus of the washed construction sand grade meets the national standards of "Construction Sand" and "Construction Pebble and Crushed Stone".

<2> This machine has almost no vulnerable parts except for the screen.

<3> Long service life, no need for maintenance for a long time. The sand washing machine has high cleanliness, reasonable structure, large processing capacity, low power consumption, and less sand loss during the sand washing process. Especially, the transmission part of the sand washing machine is isolated from water and sand, so its failure rate is much lower than the commonly used sand washing machines. It is a suitable choice for upgrading and upgrading the domestic sand washing industry.

Technical parameters:

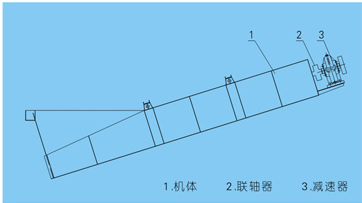

Performance characteristics of sand washing machine:

1. The sand washing machine has a simple structure and stable performance. The impeller drive bearing device is isolated from water and water receiving materials, greatly avoiding the occurrence of bearing damage caused by immersion, sand, and pollutants.

2. This type of sand washing machine has obvious advantages compared to traditional spiral sand washing machines when used for sand washing in sand and gravel fields, as follows:

<1> The loss of medium and fine sand and stone powder is minimal, and the fineness modulus of the washed construction sand grade meets the national standards of "Construction Sand" and "Construction Pebble and Crushed Stone".

<2> This machine has almost no vulnerable parts except for the screen.

<3> Long service life, no need for maintenance for a long time. The sand washing machine has high cleanliness, reasonable structure, large processing capacity, low power consumption, and less sand loss during the sand washing process. Especially, the transmission part of the sand washing machine is isolated from water and sand, so its failure rate is much lower than the commonly used sand washing machines. It is a suitable choice for upgrading and upgrading the domestic sand washing industry.

Technical parameters:

| model | Number of spirals | Spiral diameter(mm) | Tank length(mm) | Feed particle-size(mm) | Processing capacity (m/h) | Speed(r/min) | power(kw) | water consumption (t/h) | weight (t) |

| LS800 | 1 | 800 | 7500 | <=10 | 30-50 | 16 | 7.5 | 10-80 | 6.2 |

| LS1000 | 1 | 1000 | 7500 | <=10 | 50-70 | 15 | 11 | 20-100 | 7.56 |

| LS1300 | 1 | 1200 | 7500 | <=10 | 60-100 | 12 | 11 | 20-150 | 9.43 |

| LS1500 | 1 | 1400 | 9000 | <=10 | 80-130 | 10 | 15 | 40-300 | 11.46 |

| 2LS1000 | 2 | 1000 | 9000 | <=10 | 100-160 | 15 | 11×2 | 30-200 | 14.2 |

| 2LS1500 | 2 | 1400 | 9000 | <=10 | 120-200 | 10 | 15×2 | 60-300 | 13.6 |