Quanhua Mining Machinery

QUANHUA MINING MACHINERY

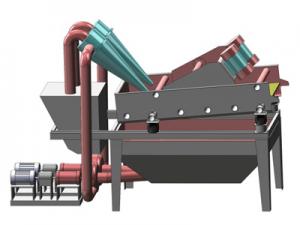

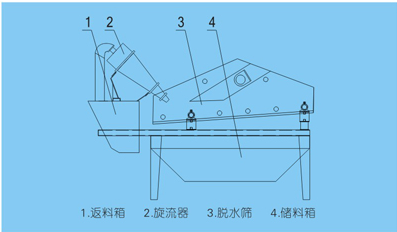

Fine sand recovery device

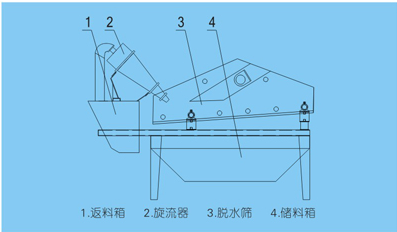

Fine sand recovery device:

At present, the vast majority of existing artificial sand production lines use wet production processes. Regardless of the form of sand washing machine used, its prominent disadvantage is the severe loss of fine sand (particles below 0.16mm), some even losing more than 20%. This not only losses production, but also seriously affects the grading of sand, causing unreasonable grading and coarse fineness modulus, greatly reducing the product quality of machine made sand. Excessive discharge of fine sand can also cause environmental pollution.

In order to solve the above problems, our company has developed the HS series fine sand recovery device system. This system is a Vanguard International Semiconductor Corporation advanced fine sand recovery device designed by our company based on the advanced technology at home and abroad and in combination with the actual situation of our country. It is widely used in the sand aggregate processing system of hydropower stations, glass raw material processing system, artificial sand production line, slime recovery of Coal preparation plant and environmental protection projects (mud purification, etc.), It can effectively solve the problem of fine sand recycling.

Technical parameters:model pump Sediment separator(mm) Dehydration screen Processing capacity(m/h) power(kw) size(inch) model area(㎡) power(kw) HS-03-300 15 3” 300 ZJS0822 1.8 1.1×2 40-126 HS-04-350 18.5 4” 350 ZJS1022 2.2 1.5×2 70-162 HS-06-500 22 6” 500 ZJS1232 3.8 3.2×2 100-220 HS-06-650 30 6” 650 ZJS1238 4.6 3.2×2 120-272 HS-06-750 37 6” 750 ZJS1438 5.3 3.2×2 180-343 HS-08-750 55 8” 750 ZJS1438 5.3 3.2×2 230-450 2HS-06-500 22×2 6” 500 ZJS1438 5.3 3.2×2 200-440 2HS-06-500 22×3 6” 500 ZJS1845 8.1 5.5×2 300-660

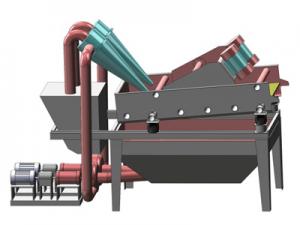

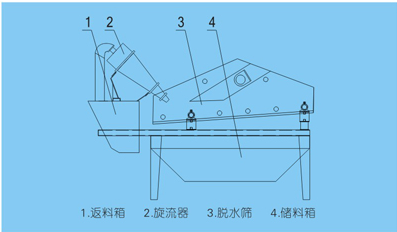

Fine sand recovery device

Fine sand recovery device:

At present, the vast majority of existing artificial sand production lines use wet production processes. Regardless of the form of sand washing machine used, its prominent disadvantage is the severe loss of fine sand (particles below 0.16mm), some even losing more than 20%. This not only losses production, but also seriously affects the grading of sand, causing unreasonable grading and coarse fineness modulus, greatly reducing the product quality of machine made sand. Excessive discharge of fine sand can also cause environmental pollution.

In order to solve the above problems, our company has developed the HS series fine sand recovery device system. This system is a Vanguard International Semiconductor Corporation advanced fine sand recovery device designed by our company based on the advanced technology at home and abroad and in combination with the actual situation of our country. It is widely used in the sand aggregate processing system of hydropower stations, glass raw material processing system, artificial sand production line, slime recovery of Coal preparation plant and environmental protection projects (mud purification, etc.), It can effectively solve the problem of fine sand recycling.

Technical parameters:

At present, the vast majority of existing artificial sand production lines use wet production processes. Regardless of the form of sand washing machine used, its prominent disadvantage is the severe loss of fine sand (particles below 0.16mm), some even losing more than 20%. This not only losses production, but also seriously affects the grading of sand, causing unreasonable grading and coarse fineness modulus, greatly reducing the product quality of machine made sand. Excessive discharge of fine sand can also cause environmental pollution.

In order to solve the above problems, our company has developed the HS series fine sand recovery device system. This system is a Vanguard International Semiconductor Corporation advanced fine sand recovery device designed by our company based on the advanced technology at home and abroad and in combination with the actual situation of our country. It is widely used in the sand aggregate processing system of hydropower stations, glass raw material processing system, artificial sand production line, slime recovery of Coal preparation plant and environmental protection projects (mud purification, etc.), It can effectively solve the problem of fine sand recycling.

Technical parameters:

| model | pump | Sediment separator (mm) | Dehydration screen | Processing capacity(m/h) | |||

| power(kw) | size(inch) | model | area(㎡) | power(kw) | |||

| HS-03-300 | 15 | 3” | 300 | ZJS0822 | 1.8 | 1.1×2 | 40-126 |

| HS-04-350 | 18.5 | 4” | 350 | ZJS1022 | 2.2 | 1.5×2 | 70-162 |

| HS-06-500 | 22 | 6” | 500 | ZJS1232 | 3.8 | 3.2×2 | 100-220 |

| HS-06-650 | 30 | 6” | 650 | ZJS1238 | 4.6 | 3.2×2 | 120-272 |

| HS-06-750 | 37 | 6” | 750 | ZJS1438 | 5.3 | 3.2×2 | 180-343 |

| HS-08-750 | 55 | 8” | 750 | ZJS1438 | 5.3 | 3.2×2 | 230-450 |

| 2HS-06-500 | 22×2 | 6” | 500 | ZJS1438 | 5.3 | 3.2×2 | 200-440 |

| 2HS-06-500 | 22×3 | 6” | 500 | ZJS1845 | 8.1 | 5.5×2 | 300-660 |