Quanhua Mining Machinery

QUANHUA MINING MACHINERY

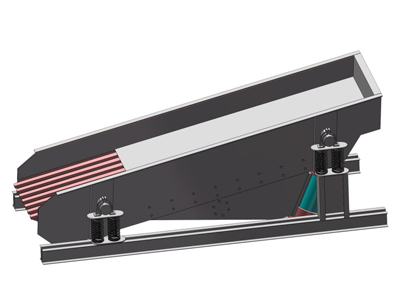

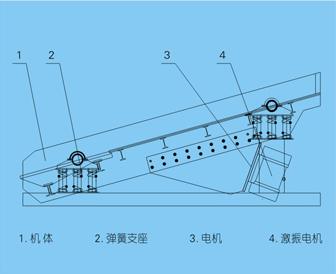

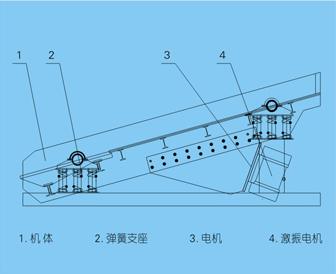

Exciting feeder

Exciting feeder :

During the production process, this series of products can uniformly, regularly, and continuously feed and receive blocky and granular materials from the storage warehouse. In the sand and gravel production line, it can continuously and evenly feed the crushing machinery and coarse screen the materials. It is widely used in crushing and screening combined equipment in industries such as metallurgy, coal mining, mineral selection, building materials, chemical industry, and abrasive.

Performance characteristics:

Stable vibration, reliable operation, and long service life; Adjustable excitation force, capable of changing and controlling flow rate at any time, convenient and stable adjustment; The vibration of the vibrating feeder is the vibration source, with low noise, low power consumption, good adjustment performance, and no material impact. Simple structure, reliable operation, convenient adjustment and installation, light weight, small volume, convenient maintenance, and when using a closed structure body, it can prevent dust pollution.

Working principle:

According to the principle of synchronous vibration of planar sound bodies, when two vibration motors operate synchronously in the opposite direction at the same angle, the inertia force in the direction of the connection of the rotation center of the vibration motor is equal in magnitude and opposite in direction, and cancels out each other. However, the component force perpendicular to the center line is in the same direction and overlaps with each other. Under the action of this inertia force, the feed chute vibrates intermittently in the direction of the combined force, thereby achieving the purpose of conveying materials.

Technical parameters:

model Maximum feeding particle size (mm) Speed (r/min) Processing capacity (m/h) Motor power (kW) JZW0810 300 960 100 1.1×2 JZW1012 400 960 150 1.1×2 JZW1315 500 960 150 1.1×2 JZW1517 600 960 200 1.5×2 JZW1719 600 960 200 1.5×2 JZW95380 700 960 300 3.2×2 JZW115490 700 960 300 5.5×2 JZW135490 800 960 400 7.5×2 JZW16055 900 960 500 11×2 JZW18055 1000 960 600 13×2

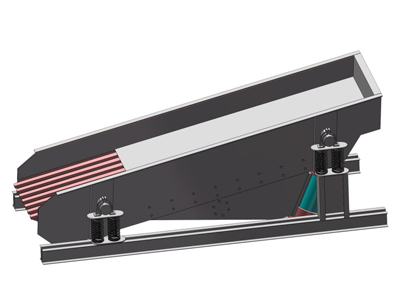

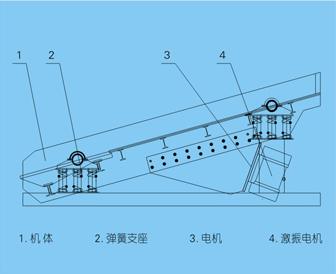

Exciting feeder

Exciting feeder :

During the production process, this series of products can uniformly, regularly, and continuously feed and receive blocky and granular materials from the storage warehouse. In the sand and gravel production line, it can continuously and evenly feed the crushing machinery and coarse screen the materials. It is widely used in crushing and screening combined equipment in industries such as metallurgy, coal mining, mineral selection, building materials, chemical industry, and abrasive.

Performance characteristics:

Stable vibration, reliable operation, and long service life; Adjustable excitation force, capable of changing and controlling flow rate at any time, convenient and stable adjustment; The vibration of the vibrating feeder is the vibration source, with low noise, low power consumption, good adjustment performance, and no material impact. Simple structure, reliable operation, convenient adjustment and installation, light weight, small volume, convenient maintenance, and when using a closed structure body, it can prevent dust pollution.

Working principle:

According to the principle of synchronous vibration of planar sound bodies, when two vibration motors operate synchronously in the opposite direction at the same angle, the inertia force in the direction of the connection of the rotation center of the vibration motor is equal in magnitude and opposite in direction, and cancels out each other. However, the component force perpendicular to the center line is in the same direction and overlaps with each other. Under the action of this inertia force, the feed chute vibrates intermittently in the direction of the combined force, thereby achieving the purpose of conveying materials.

Technical parameters:

During the production process, this series of products can uniformly, regularly, and continuously feed and receive blocky and granular materials from the storage warehouse. In the sand and gravel production line, it can continuously and evenly feed the crushing machinery and coarse screen the materials. It is widely used in crushing and screening combined equipment in industries such as metallurgy, coal mining, mineral selection, building materials, chemical industry, and abrasive.

Performance characteristics:

Stable vibration, reliable operation, and long service life; Adjustable excitation force, capable of changing and controlling flow rate at any time, convenient and stable adjustment; The vibration of the vibrating feeder is the vibration source, with low noise, low power consumption, good adjustment performance, and no material impact. Simple structure, reliable operation, convenient adjustment and installation, light weight, small volume, convenient maintenance, and when using a closed structure body, it can prevent dust pollution.

Working principle:

According to the principle of synchronous vibration of planar sound bodies, when two vibration motors operate synchronously in the opposite direction at the same angle, the inertia force in the direction of the connection of the rotation center of the vibration motor is equal in magnitude and opposite in direction, and cancels out each other. However, the component force perpendicular to the center line is in the same direction and overlaps with each other. Under the action of this inertia force, the feed chute vibrates intermittently in the direction of the combined force, thereby achieving the purpose of conveying materials.

Technical parameters:

| model | Maximum feeding particle size (mm) | Speed (r/min) | Processing capacity (m/h) | Motor power (kW) |

| JZW0810 | 300 | 960 | 100 | 1.1×2 |

| JZW1012 | 400 | 960 | 150 | 1.1×2 |

| JZW1315 | 500 | 960 | 150 | 1.1×2 |

| JZW1517 | 600 | 960 | 200 | 1.5×2 |

| JZW1719 | 600 | 960 | 200 | 1.5×2 |

| JZW95380 | 700 | 960 | 300 | 3.2×2 |

| JZW115490 | 700 | 960 | 300 | 5.5×2 |

| JZW135490 | 800 | 960 | 400 | 7.5×2 |

| JZW16055 | 900 | 960 | 500 | 11×2 |

| JZW18055 | 1000 | 960 | 600 | 13×2 |