Quanhua Mining Machinery

QUANHUA MINING MACHINERY

Single cylinder hydraulic cone crusher

GT series single cylinder hydraulic cone crusher

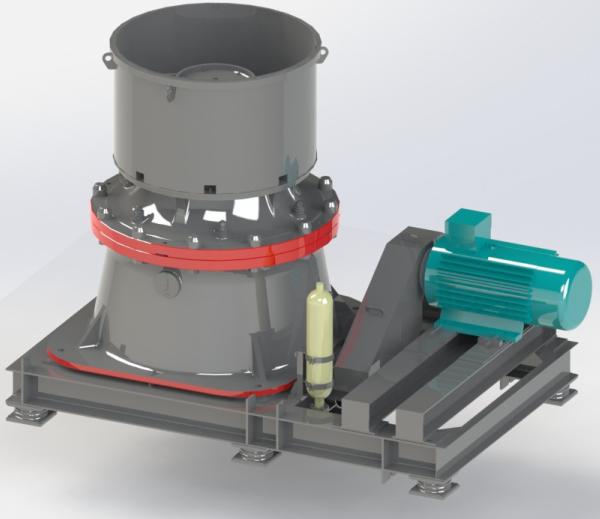

The GT series single cylinder hydraulic cone crusher has advanced design and a compact body with strong crushing capacity. It has high crushing efficiency and produces products with good particle shape. Tight edge discharge outlet (CSS)

Through hydraulic adjustment, users can choose automatic control. Various types of crushing chambers and many other high-performance features. Each model can meet the diverse needs of users,

Easy to use and maintain, with high operation rate.?

The GTS and GTH series single cylinder hydraulic cone crushers of Huzhou Quanhua Mining Machinery have a wide range of applications. By selecting the appropriate crushing chamber type and eccentricity

Easily adapt to different production requirements. Our single cylinder hydraulic cone crusher is used as a two-stage and three-stage crusher, with a compact structure and easy maintenance design

The characteristics also make this equipment a good choice for mining machinery and equipment.

The GT series single cylinder hydraulic cone crusher provides automatic overload protection and can be equipped with an intelligent ore discharge automatic adjustment system. This system can improve the utilization rate of cone crushers

And automatically adapt to changes in feeding conditions. Through continuous testing and compensation for crusher liner wear, users can fully utilize the crusher liner and easily develop liners

Plan for board replacement and equipment maintenance. This system can also help users maintain full load feeding of the crusher, achieve laminated crushing, and improve crushing efficiency

Crushing efficiency, product quality, and lining utilization rate.

Crushing chamber

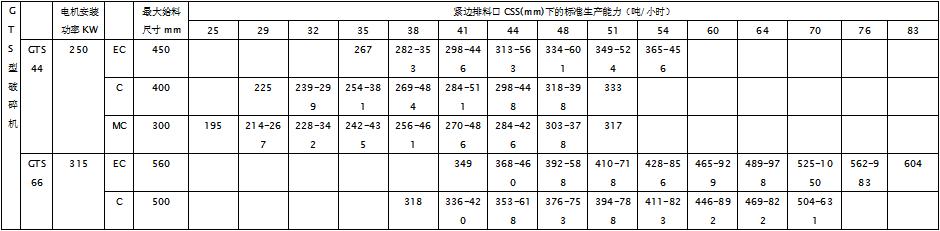

GTS crusher

There are three standard crushing chamber types to choose from:

MC=medium thick

C=Coarse?

EC=Extra Coarse

GTH crusher

Multiple crushing chamber types available for selection:

EEF=Ultra fine

EF=Extra fine

EFX=quasi fine

F=Fine

MF=medium fine

M=Medium

MC=medium thick

C=Coarse

CX=quasi extra thick

EC=Extra Coarse

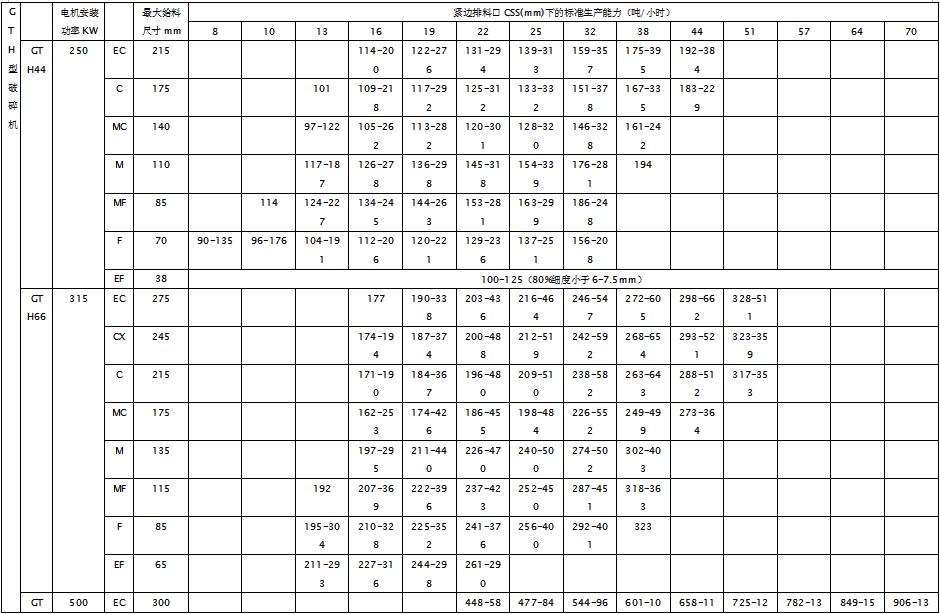

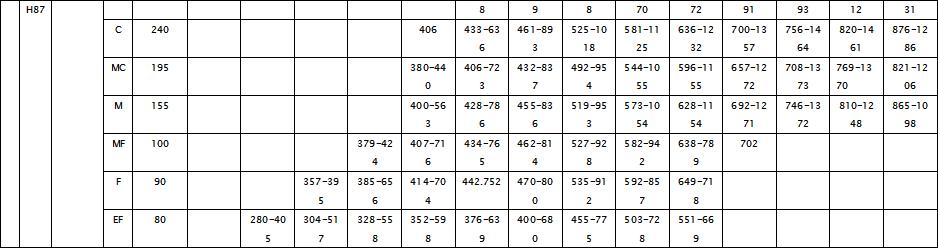

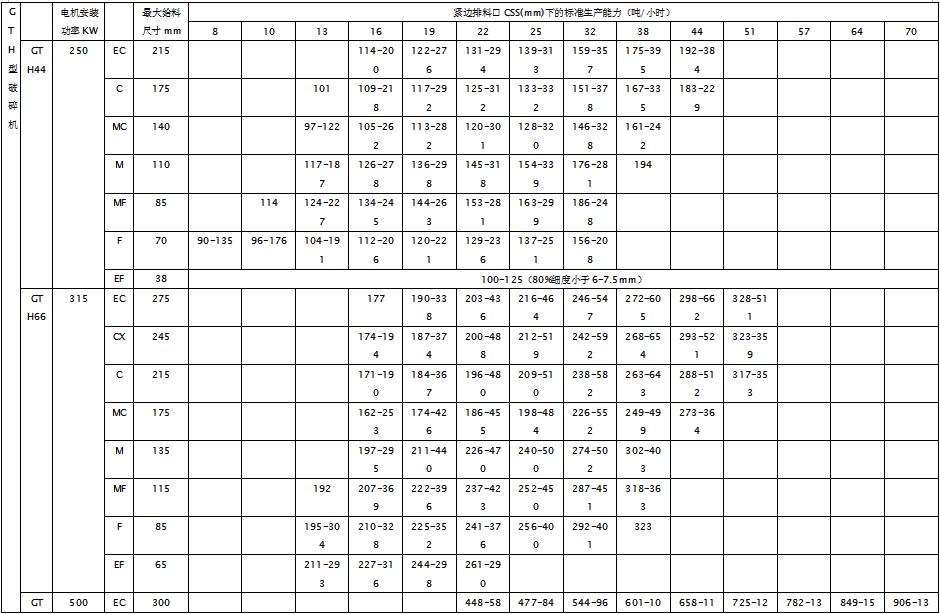

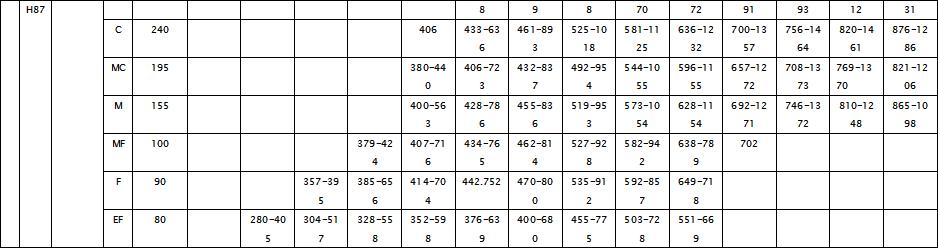

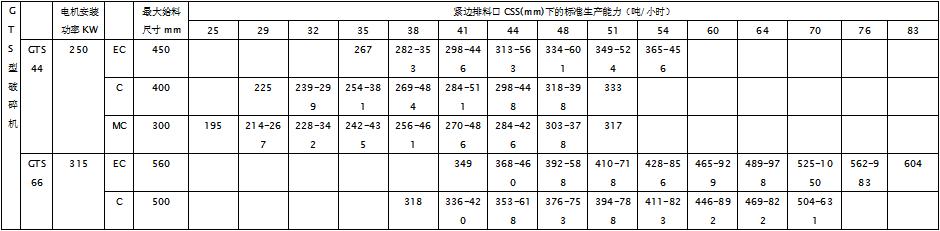

Production capacity: T/H

The provided data is only an approximate indicator of the production performance of the crusher.

The data in the table is for the performance of the crusher during open-circuit production of dry materials with a bulk density of 1600kg/m, and it is assumed that the maximum particle size of the feed is the crusher

The maximum allowable feed particle size, excluding fine materials smaller than the crusher's tight edge discharge port (CSS).

Due to the selected eccentricity, crushing ratio, crushing work index (Wi) of the material, feed particle size composition, cyclic load, and water content in the feed

The amount of mud and other factors can affect the capacity of the crusher, so please consult us further for specific application situations.

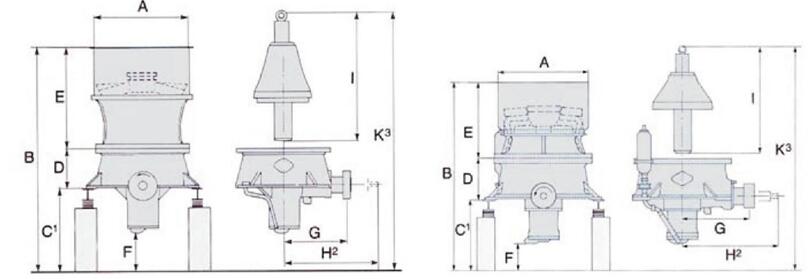

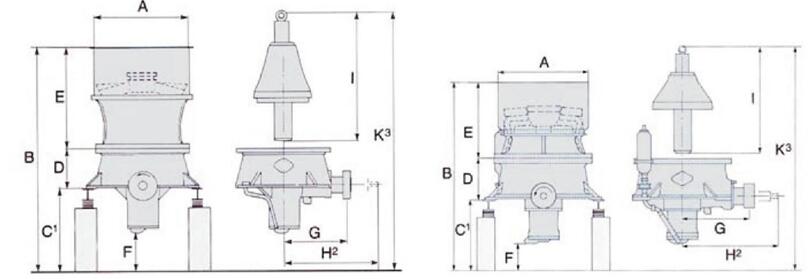

Size: mm

Dim.

GTS44

GTS66

GTH44

GTH66

GTH87

A

Φ2000

Φ2800

Φ1540

Φ1954

Φ2450

B

4075

5100

3410

4215

5475

C1

1300

1600

1300

1600

2200

D

745

860

745

860

1228

E

2030

2640

1365

1755

2045

F

452

631

452

631

998

G

1280

1497

1280

1497

1824

H2

1900

2156

1900

2156

2850

I

2420

2895

1985

2344

3095

K

4930

5355

4000

4835

6600

The dimensions in the table are only used to guide the preparation work before installation and are not used for foundation construction, etc.

Weight: KG

GTS44

GTS66

GTH44

GTH66

GTH87

Maximum during maintenance

Lifting capacity

8100

16500*

4700**

7400**

13000**

total weight

19300

35000

14300**

23500**

50000**

*16500 kg=upper frame assembly+arm frame assembly.

9700 kg=upper frame assembly

**Suitable for fine chamber crushers. If it is a coarse chamber crusher, these weights will be reduced. For the GTH440 model, there will be a reduction of 600 kilograms; For the GTH660 model, there will be a reduction of 600 kilograms; For the GTH870 model, there will be a reduction of 600 kilograms.

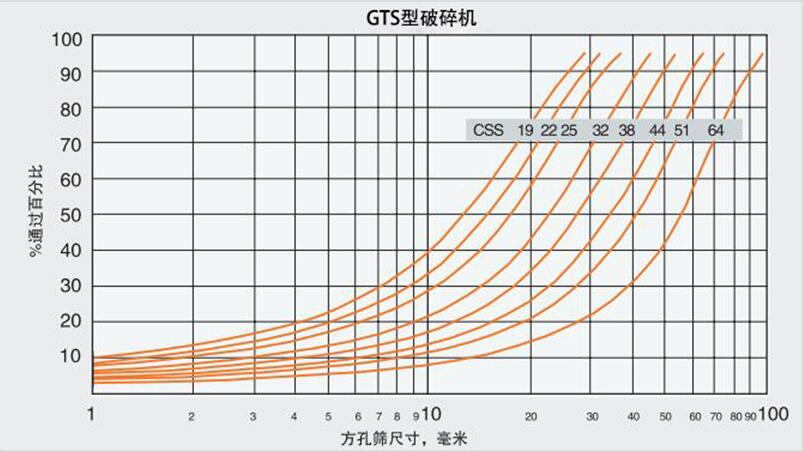

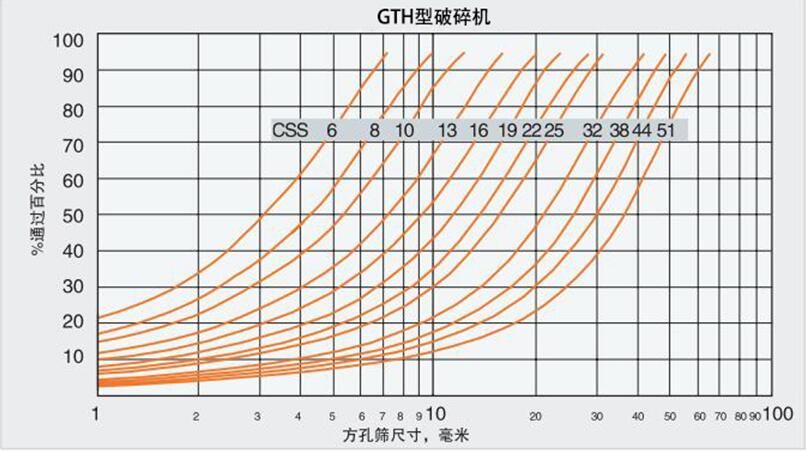

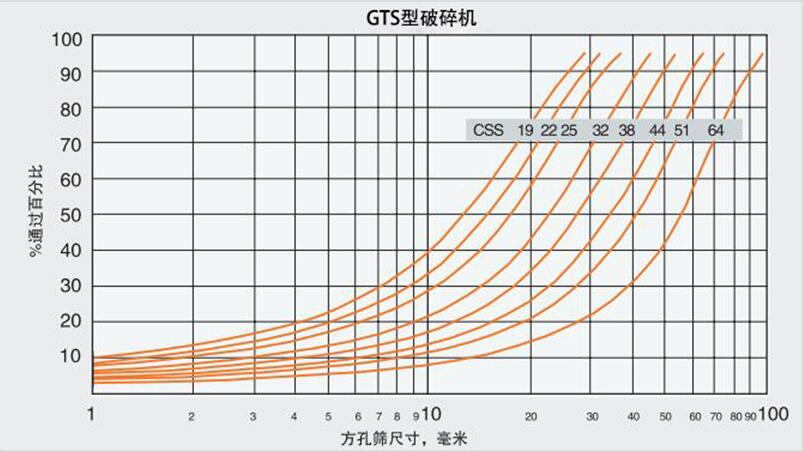

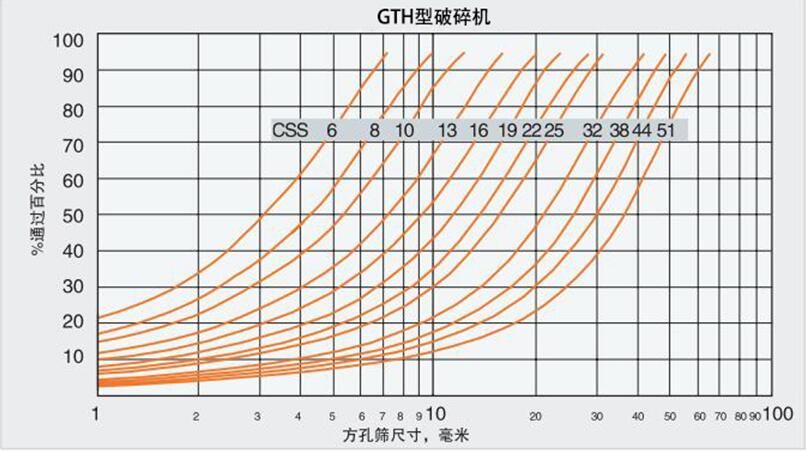

Product granularity curve

The particle size curve of the product and the percentage of crushed products smaller than the tight edge discharge port (square hole, millimeter) are related to the material's crushing work index (Wi), feed particle size characteristics, and other factors.

Single cylinder hydraulic cone crusher

The GT series single cylinder hydraulic cone crusher has advanced design and a compact body with strong crushing capacity. It has high crushing efficiency and produces products with good particle shape. Tight edge discharge outlet (CSS)

Through hydraulic adjustment, users can choose automatic control. Various types of crushing chambers and many other high-performance features. Each model can meet the diverse needs of users,

Easy to use and maintain, with high operation rate.?

The GTS and GTH series single cylinder hydraulic cone crushers of Huzhou Quanhua Mining Machinery have a wide range of applications. By selecting the appropriate crushing chamber type and eccentricity

Easily adapt to different production requirements. Our single cylinder hydraulic cone crusher is used as a two-stage and three-stage crusher, with a compact structure and easy maintenance design

The characteristics also make this equipment a good choice for mining machinery and equipment.

The GT series single cylinder hydraulic cone crusher provides automatic overload protection and can be equipped with an intelligent ore discharge automatic adjustment system. This system can improve the utilization rate of cone crushers

And automatically adapt to changes in feeding conditions. Through continuous testing and compensation for crusher liner wear, users can fully utilize the crusher liner and easily develop liners

Plan for board replacement and equipment maintenance. This system can also help users maintain full load feeding of the crusher, achieve laminated crushing, and improve crushing efficiency

Crushing efficiency, product quality, and lining utilization rate.

Crushing chamber

GTS crusher

There are three standard crushing chamber types to choose from:

MC=medium thick

C=Coarse?

EC=Extra Coarse

GTH crusher

Multiple crushing chamber types available for selection:

EEF=Ultra fine

EF=Extra fine

EFX=quasi fine

F=Fine

MF=medium fine

M=Medium

MC=medium thick

C=Coarse

CX=quasi extra thick

EC=Extra Coarse

Production capacity: T/H

The provided data is only an approximate indicator of the production performance of the crusher.

The data in the table is for the performance of the crusher during open-circuit production of dry materials with a bulk density of 1600kg/m, and it is assumed that the maximum particle size of the feed is the crusher

The maximum allowable feed particle size, excluding fine materials smaller than the crusher's tight edge discharge port (CSS).

Due to the selected eccentricity, crushing ratio, crushing work index (Wi) of the material, feed particle size composition, cyclic load, and water content in the feed

The amount of mud and other factors can affect the capacity of the crusher, so please consult us further for specific application situations.

Size: mm

Dim. | GTS44 | GTS66 | GTH44 | GTH66 | GTH87 |

A | Φ2000 | Φ2800 | Φ1540 | Φ1954 | Φ2450 |

B | 4075 | 5100 | 3410 | 4215 | 5475 |

C1 | 1300 | 1600 | 1300 | 1600 | 2200 |

D | 745 | 860 | 745 | 860 | 1228 |

E | 2030 | 2640 | 1365 | 1755 | 2045 |

F | 452 | 631 | 452 | 631 | 998 |

G | 1280 | 1497 | 1280 | 1497 | 1824 |

H2 | 1900 | 2156 | 1900 | 2156 | 2850 |

I | 2420 | 2895 | 1985 | 2344 | 3095 |

K | 4930 | 5355 | 4000 | 4835 | 6600 |

The dimensions in the table are only used to guide the preparation work before installation and are not used for foundation construction, etc.

Weight: KG

| GTS44 | GTS66 | GTH44 | GTH66 | GTH87 |

Maximum during maintenance |

|

|

|

|

|

Lifting capacity | 8100 | 16500* | 4700** | 7400** | 13000** |

total weight | 19300 | 35000 | 14300** | 23500** | 50000** |

*16500 kg=upper frame assembly+arm frame assembly.

9700 kg=upper frame assembly

**Suitable for fine chamber crushers. If it is a coarse chamber crusher, these weights will be reduced. For the GTH440 model, there will be a reduction of 600 kilograms; For the GTH660 model, there will be a reduction of 600 kilograms; For the GTH870 model, there will be a reduction of 600 kilograms.

Product granularity curve

The particle size curve of the product and the percentage of crushed products smaller than the tight edge discharge port (square hole, millimeter) are related to the material's crushing work index (Wi), feed particle size characteristics, and other factors.